Problem

Transitioning a part from traditional manufacturing to 3D printing is not always a straightforward process, even for field experts, with material selection being one key challenge.

During the process of qualifying and prototyping a part, material and Additive Manufacturing (AM) experts must access a comprehensive industry material database, containing both basic and detailed material properties.

To make a well-informed and structured decision on the appropriate AM material for 3D printing, the user requires guidance in navigating the selection process among over 1,200 industry-tested materials.

Business goal

A concrete roadmap with features priorities matching customers’ demands.

Modular design of the feature to build on and expand release after release, providing at each step the identified user value within the different stories/scenarios.

User impact goal

The end goal of the tool is a “feed” of relevant AM materials that automatically match the part technical and production requirements, giving experts a focused comparison on relevant material opportunities.

The tool aimed to automate the manual work of filtering and searching through the entire material database to find relevant replacement options, considerably reducing time & effort.

Customers

Large enterprises and equipment manufacturers in the transportation, defense and energy sectors. Their primary goal is to digitise and analyse part inventories to identify opportunities for additive manufacturing, to reduce inventory and stock costs while creating a more sustainable supply chain.

User Research

During the first phase of the project, I interviewed several clients, focusing on the most unknown questions.

How the material decision-making process looks like and at which step in the flow the user could benefit from the material library?

Which production part goals and requirements are known/needed to search and choose a correct replacement material?

How the production requirements are established and where this information is stored?

Which material properties are more important to make a decision?

Market Analysis

The analysis I ran covered 3 different paths

similar tools on the market to compare and gather inspiration

applications that simulate the same experience and journey

best practices and guidelines to design effective and user-friendly interfaces to filter and search through large databases

Note: Understanding the best practices helped me analyse existing competitive tools through this lens as well, which proved valuable for informing later design decisions.

First draft of the comparison and notes from the competition analysis

User Stories

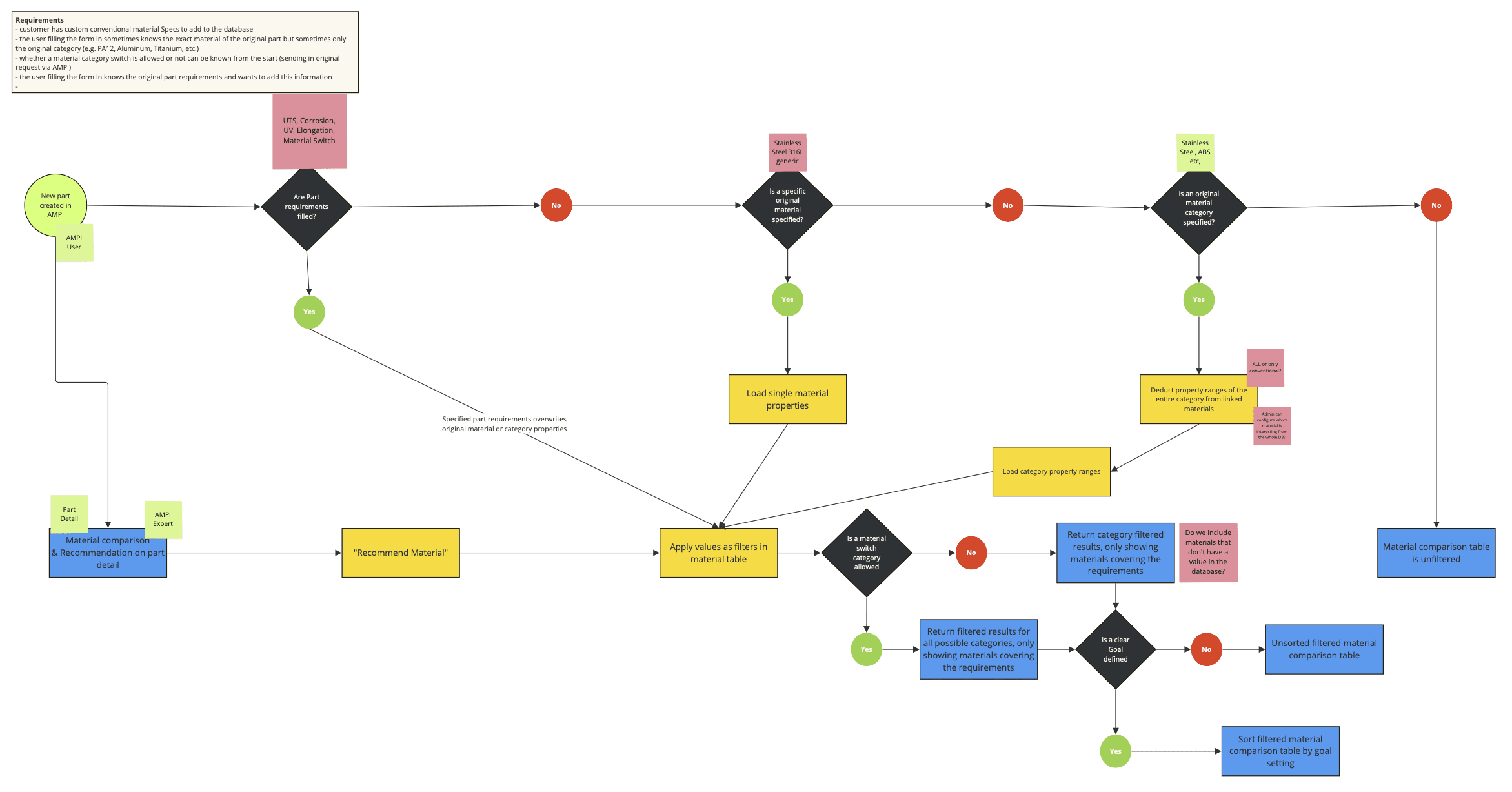

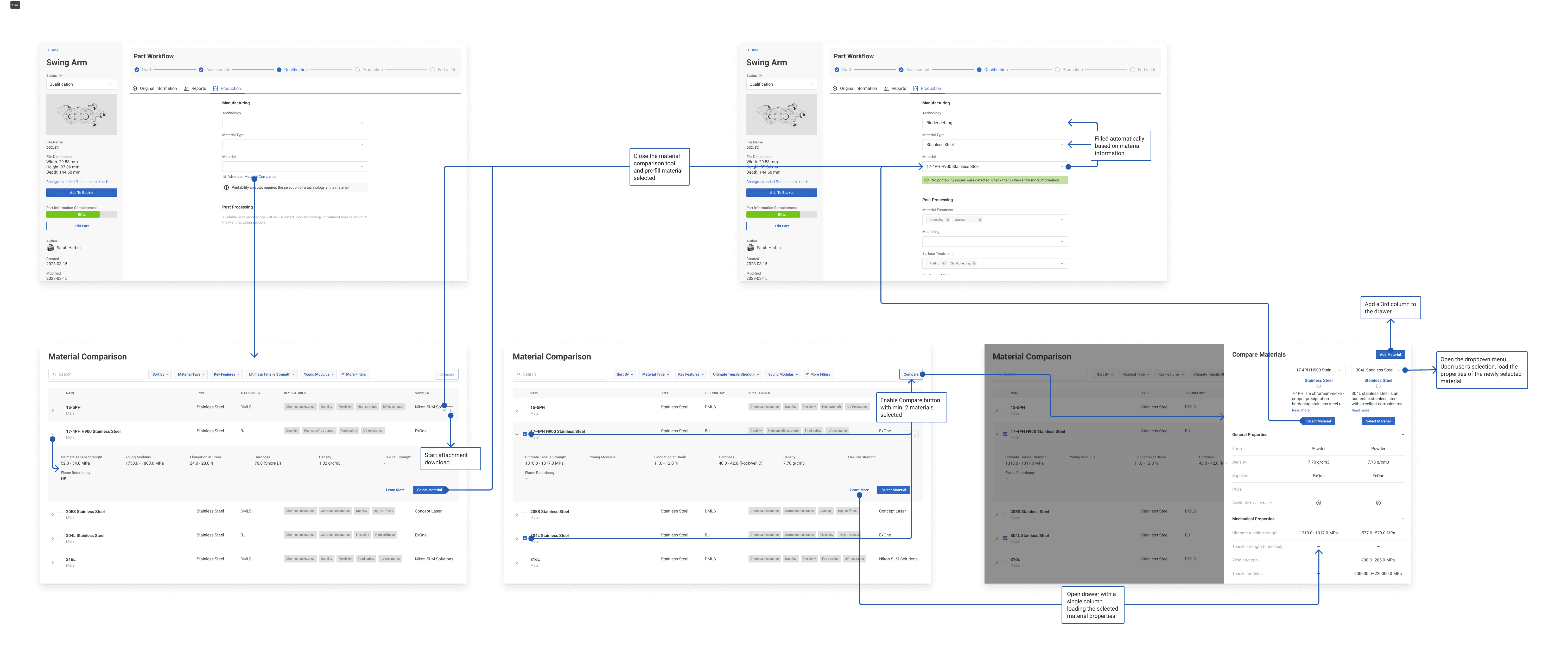

While mapping the user flow, I discovered that achieving our end goal — providing a smart "feed" of matching materials based on part requirements — would require improving and expanding capabilities in a different area of the software. Here the user is requested to fill in a form, either automatically or manually, with the relevant information and requirements.

I therefore divided the project into 4 dependent stages, each reflecting a main user story and delivering increasing value step by step.

1

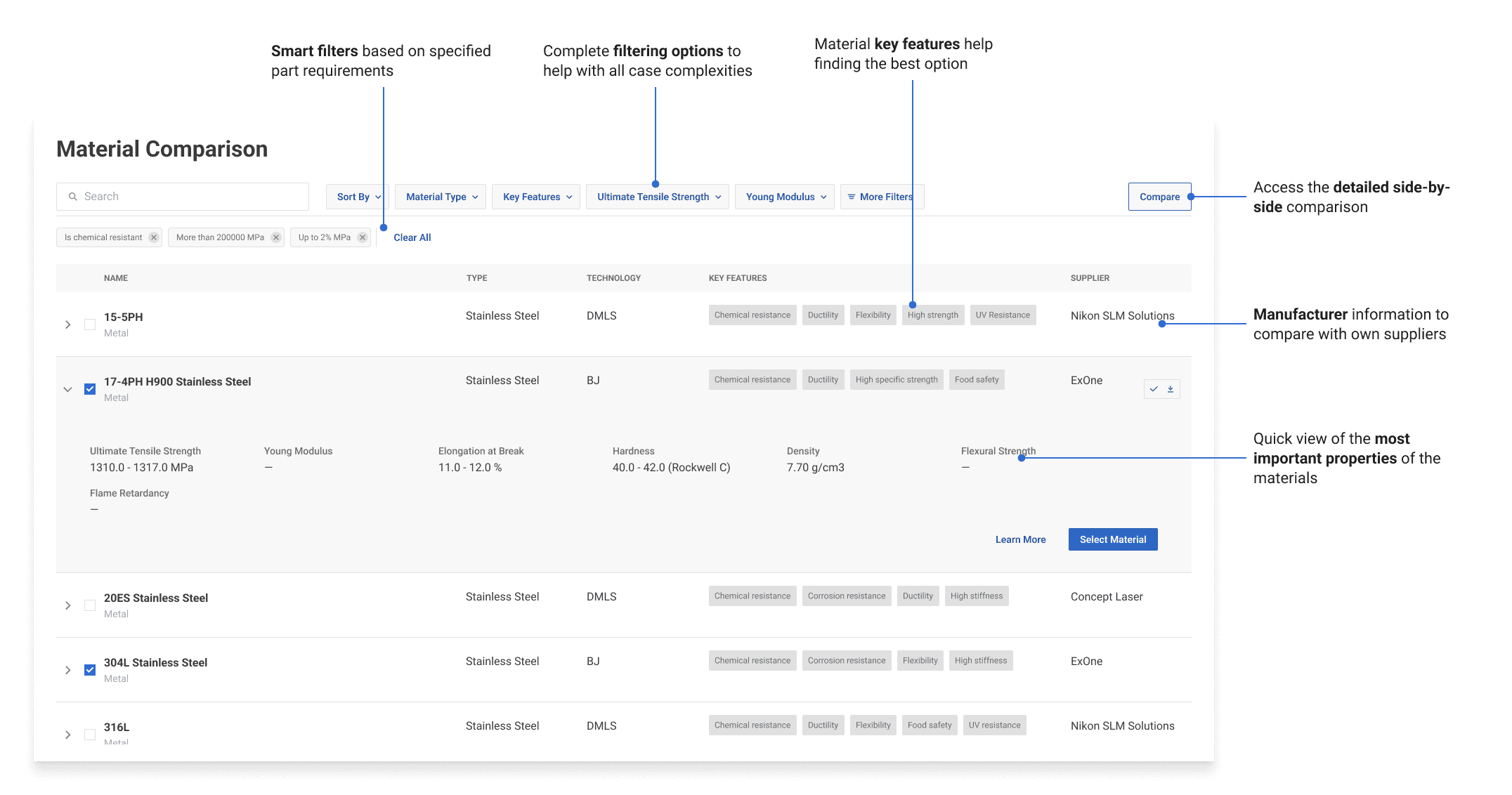

User navigates the full material library, filters and searches using highest-priority properties, then selects a material to proceed further with the part production ordering.

This is the highest priority story to maintain workflow continuity.

2

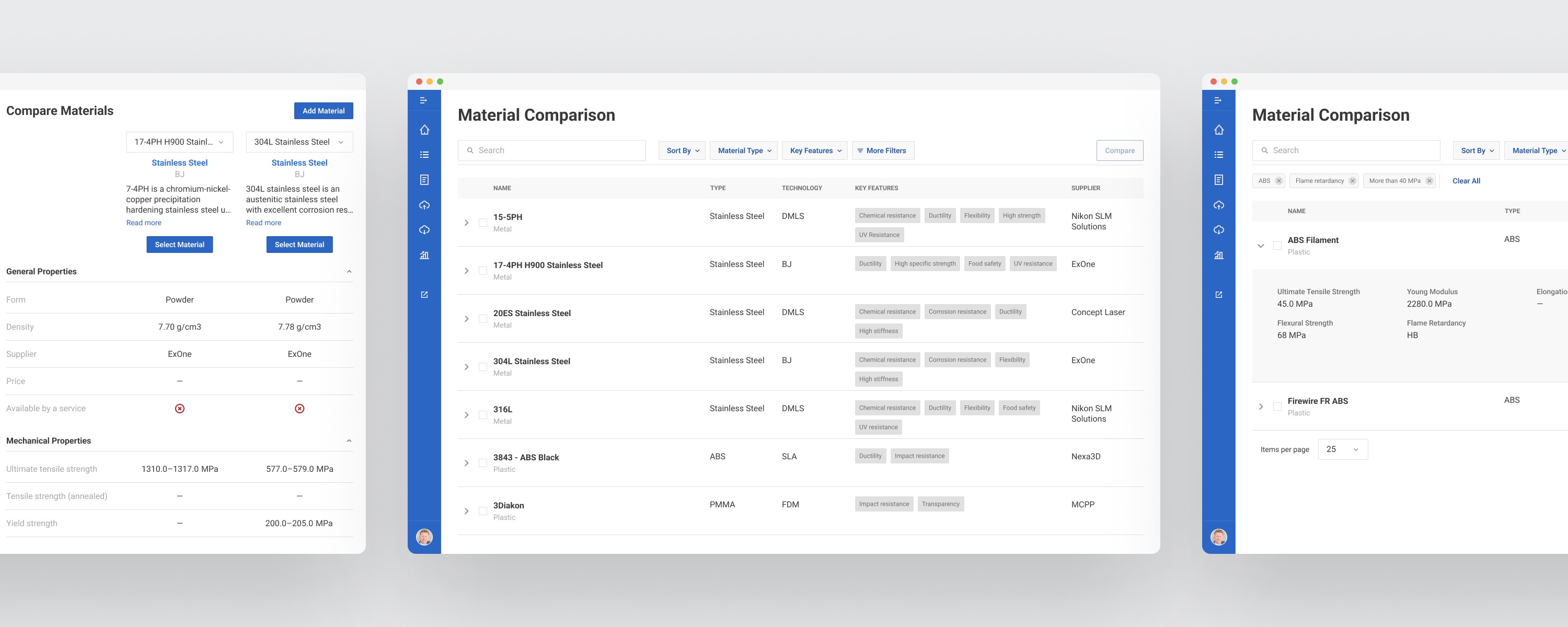

User performs detailed side-by-side comparisons of 2-3 materials to select the optimal option

It would provide a more advanced analysis tool.

3

User inputs detailed part requirements to afterwards guide material and production method selection

This story connects to another software area and it was necessary to further develop smart material comparison capabilities.

4

User chooses from an automatically and smartly filtered list of materials based on their specified part requirements.

Flow and logic of the material recommendation

Wireframing & Testing

Once I created the first wireframes, I tested the flows and the interfaces with both internal stakeholders and customers to:

Validate if the new material tool was easily accessible

Validate if the user could find the desired material and all the information needed to make a decision

If the tool was driving a more informed decision on the material

Example of a user flow in Figma

Key Findings

The three-layer information structure received positive feedback and appreciation:

Quick vs. in-depth analysis based on case complexity

Easy tool navigation regardless of user expertise level

Users could easily perform filters and searches.

However, users had difficulty accessing the tool in the first interaction.

Results

3 Main customers successfully integrated the tool within their processes

Reduced time spent finding suitable materials

Enhanced material knowledge and understanding for less experienced users

Note: While I already designed the smart tool's logic with developers and internal stakeholders to meet customers needs, I departed the company before releasing the final two user stories and collecting comprehensive project metrics.

Solution overview with key features highlights

Takeaways

Clarify all hypothesis and spot the most uncertain ones

Not only this project, but working for this company and the specific customers’ type taught me to focus and research on the most uncertain hypotheses. Some conditions — develop a software early on in the market adoption, clients having large integrated software ecosystems, customers with well-established processes and organisations requiring multiple acceptance level — posed a few challenges which sometimes were in contrast with the fast pace of a start-up. Focusing on the right questions and people was fundamental to find compromises and move further in the design process.

Deliver user value for every building block

I led this project from research through to implementation, consistently maintaining a clear overview and a focus on the long-term objectives. I designed and built modular components that could be easily expanded in later stages, while ensuring that each phase delivered tangible value to the user. This approach is crucial for the success of large-scale projects, particularly those that directly impact and integrate with existing systems and interfaces.